Why Coarse Calcium Carbonate Powder Is Ideal for Wall Putty Manufacturing in Southeast Asia

Discover why coarse calcium carbonate powder (CaCO₃) is the preferred wall putty filler in Southeast Asia — especially in the Philippines construction materials market. Learn its benefits, production process, and applications. Contact us for CaCO₃ quotation or download our product catalogue.

1. The Growing Need for High-Quality Fillers in Southeast Asia

As construction activity continues to surge across Southeast Asia, especially in the Philippines, demand for durable, cost-efficient, and easy-to-apply wall putty fillers has never been higher.

Among the essential raw materials for wall putty manufacturing, coarse calcium carbonate powder (CaCO₃) has emerged as a leading choice for local producers due to its superior performance, availability, and cost-effectiveness.

Our company specializes in supplying premium coarse calcium carbonate that meets strict quality standards — ensuring consistent performance for manufacturers in the Philippines construction materials sector and beyond.

2. What Makes Coarse Calcium Carbonate the Perfect Wall Putty Filler?

2.1. Excellent as a Functional Filler

Coarse calcium carbonate serves as a cost-effective filler that improves bulk and smoothness without compromising strength. Its coarser particle size allows better control over viscosity, making it ideal for wall putty formulations that require smooth application and fast drying time.

2.2. Improved Coverage and Surface Finish

When blended into wall putty, coarse CaCO₃ enhances surface uniformity, reduces cracks, and delivers a superior finish for painting or coating. Compared to ultra-fine fillers, it offers better mechanical stability and enhances the putty’s spreading ability.

2.3. Chemical and Physical Stability in Tropical Climates

The Philippines’ hot and humid environment poses unique challenges for construction materials. Coarse calcium carbonate exhibits excellent moisture resistance and chemical inertness, minimizing shrinkage or peeling even under high humidity.

That makes it the perfect filler for tropical construction markets like Southeast Asia.

2.4. Cost Optimization and Sustainable Sourcing

Compared to silica or polymer-based fillers, CaCO₃ provides a lower production cost while maintaining high performance. Its natural abundance and ease of processing help local wall putty manufacturers reduce raw material costs and achieve higher profit margins.

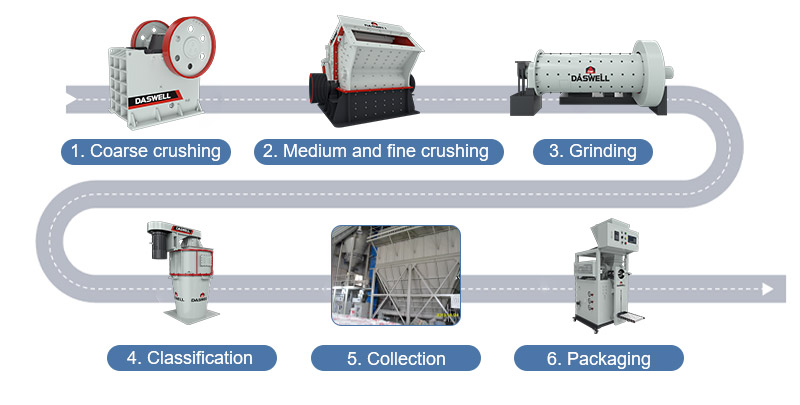

3. The Production Process of Coarse Calcium Carbonate Powder

Below is a typical industrial process for manufacturing coarse CaCO₃ suitable for wall putty filler use:

Step 1: Raw Material Mining

High-purity limestone or calcite is carefully mined and selected for chemical consistency and whiteness.

Step 2: Primary Crushing

The raw stones are crushed using jaw or hammer crushers into smaller, manageable pieces.

Step 3: Grinding and Classification

Material passes through ball mills or vertical mills, producing controlled particle sizes. For coarse calcium carbonate, larger particles are intentionally retained to achieve the desired texture and filler properties.

Step 4: Drying and Packaging

The powder is dried, moisture levels are checked, and the final product is packed in moisture-proof bags for delivery.

Step 5: Quality Control

Every batch is tested for whiteness, particle distribution, and purity to ensure that the final product meets international wall putty manufacturing standards.

✅ With modern equipment and strict QC systems, our factory ensures every batch of CaCO₃ powder provides consistent quality for wall putty producers.

4. Applications in Wall Putty Manufacturing in the Philippines and Southeast Asia

4.1. Market Trends in the Philippines Construction Industry

The Philippines has one of the fastest-growing construction sectors in ASEAN, driven by urban development and infrastructure projects. Wall putty is a key finishing material, and the use of coarse calcium carbonate as a filler is a smart way for manufacturers to balance cost and performance.

4.2. Role of CaCO₃ Filler in Wall Putty

Enhances the coverage and smoothness of wall putty.

Improves durability and surface adhesion.

Reduces dependence on more expensive polymers or cement.

Stabilizes the product under the humid tropical climate of the Philippines.

4.3. Benefits for Manufacturers and End Users

For manufacturers: Lower input costs, better control of consistency, and easier formulation management.

For applicators and consumers: Smooth surface, minimal cracks, and better adhesion for paints.

🌴 Coarse calcium carbonate helps Philippine wall putty producers deliver high-quality, tropical-resistant products at competitive prices.

5. Our Company: Reliable Supplier of Coarse Calcium Carbonate in Southeast Asia

As a trusted CaCO₃ manufacturer and exporter, we are committed to providing high-purity coarse calcium carbonate for the construction and coating industries.

Our Strengths

Modern manufacturing facilities equipped with advanced grinding and classification systems.

Consistent quality control, verified by ISO and SGS certifications.

Strategic supply chain coverage across Vietnam, Thailand, and the Philippines.

Technical consultation to help optimize your wall putty formulation.

The use of coarse calcium carbonate powder in wall putty manufacturing offers exceptional technical and economic advantages for Southeast Asian producers. Its chemical stability, cost-efficiency, and excellent performance under tropical conditions make it the ideal wall putty filler for markets like the Philippines.

Whether you are a wall putty manufacturer, construction material distributor, or formulation engineer, partnering with a trusted CaCO₃ supplier ensures long-term consistency and quality.

📩 Contact us today to get a customized CaCO₃ quotation.

Contact: salesmanager@tankymineral.com.vn

Website: www.tankymineral.com.vn

_1.jpg?1762917566483)