Mine

Tan Ky Mineral Processing Joint Stock Company currently owns a high quality limestone quarry in Eo Cat area, Tan Xuan commune, Tan Ky district, Nghe An province under the Mining License No. 59 / GP. -BTNMT

About us

Tan Ky Mineral Processing Joint Stock Company has a factory located in Zone C, Nam Cam Industrial Zone, Nghi Xa Commune, Nghi Lộc District, Nghe An Province. Our factory location is very convenient for transportation (about 5km far from Cua Lo port, 70km from Nghi Son port, 6km from Quan Hanh cargo train station, 17km from Vinh airport and 2km from 1A Highway). Our main business is manufacturing of calcium carbonate (CaCO3) products, including ultrafine calcium carbonate powder (Ground calcium carbonate- GCC) and stearic acid coated calcium carbonate powder with a D97 size of 5um (D50 from 0.8 Mm) or more, as an additive for paint, plastics, rubber, paper, cosmetics, aquaculture, animal feed, building materials in construction,…

Xem chi tiếtFactory

Our factory was built on a total area of about 3 ha, located in Area C, Nam Cam Industrial Park, Nghi Xa Commune, Nghi Loc District, Nghe An Province. The company has a very convenient location for product movement according to customer requirements (5km from Cua Lo Port, 6km from Quan Hanh Cargo Railway Station, 17km from Vinh Airport and 2km from National Highway 1A).

Xem chi tiết

Vision and Mission

With long term investment combining modern advanced technology, Tan Ky Mineral aim to be a leading manufacturer of calcium carbonate powder from Vietnam

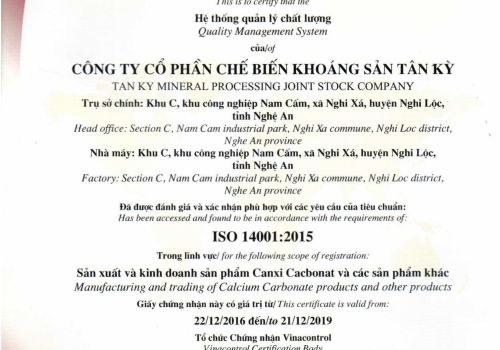

Xem chi tiếtCertification

Tan Ky Mineral Processing Joint Stock Company has been evaluated and certified in accordance with ISO 9001: 2015 and ISO 14001: 2015 standards in manufacturing Calcium Carbonate products.

Xem chi tiết

Laboratory

The laboratory of Tan Ky Mineral Processing Joint Stock Company plays an important role in quality control as well as research on quality improvement to meet the needs of customers.

Xem chi tiết

Quality Control

Our commitment to quality and environment encompasses our products and services, which we ensure meet industry standards through the implementation of ISO9001:2015 quality management system, ISO14001:2015 environment management system.

Xem chi tiết

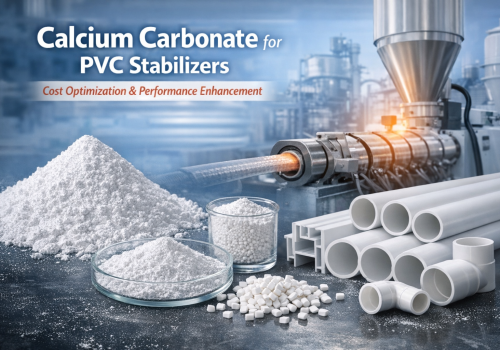

Calcium Carbonate for PVC Stabilizers: Improving Stability and Performance

In the modern plastics industry, Calcium Carbonate (CaCO₃) plays a vital role as a functional filler in many applications, particularly in Polyvinyl Chloride (PVC) formulations. Among these applications, PVC stabilizers rely on high-quality calcium carbonate to enhance processing stability, improve product consistency, and optimize production costs.

With the growing demand for durable and cost-effective PVC products, manufacturers are increasingly seeking reliable mineral fillers that can support stabilizer performance without compromising quality.

This article explains how calcium carbonate improves PVC stabilizer performance and why selecting the right grade is essential for optimal results.

Xem chi tiết

Calcium Carbonate for PVC Stabilizers – Cost Optimization and Performance Enhancement

High-quality calcium carbonate for PVC stabilizers. Improve dispersion, color stability and reduce cost with Tan Ky Mineral’s consistent CaCO₃ solutions.

Xem chi tiết

High Quality Calcium Carbonate Powder for Cost-Effective Manufacturing in India

Premium Calcium Carbonate Powder (CaCO₃) for Indian manufacturers. Reduce production cost, stable quality, ideal for plastic and masterbatch industries.

Calcium Carbonate (CaCO₃) Powder: Features and Applications in the Philippines

Discover the technical features, benefits, and industrial applications of calcium carbonate powder in the Philippines. An ideal solution for plastic, construction, and coating industries.

Xem chi tiết

Vietnam Calcium Carbonate Powder Supplier for India | High Quality CaCO₃

Reliable Vietnam calcium carbonate powder supplier for India. High purity CaCO₃, competitive price, stable supply for plastic, paint & rubber industries.

Calcium Carbonate Powder for Philippines | Reliable CaCO₃ Supplier from Vietnam

High-quality Calcium Carbonate (CaCO₃) powder for plastic, paint, and construction industries in the Philippines. Stable quality, competitive pricing, export-ready supply from Vietnam.

Calcium Carbonate Powder Price in India | Latest Buyer Guide 2026

Discover the latest calcium carbonate powder price in India. Learn price ranges, cost factors, applications, and why importing from Vietnam helps Indian buyers reduce costs.

Vietnamese Calcium Carbonate Powder | A Production Engineer’s Perspective

An in-depth analysis of Vietnamese calcium carbonate powder (CaCO₃) from a production engineer’s perspective, focusing on process stability, equipment wear, and real industrial performance.

Calcium Carbonate Powder for Bangladesh: Reduce Cost & Improve Quality

High-quality calcium carbonate powder for Bangladesh industries. Stable quality, cost-saving, ideal for plastic, paint, cement. Free samples available

Calcium Carbonate (CaCO₃) Powder – Technical Specifications for Philippines Market

High-purity calcium carbonate (CaCO₃) powder with stable quality, high whiteness, and multiple particle sizes. Suitable for plastic, paint, rubber, and construction industries in the Philippines.

Vietnamese Stone Powder – Premium Natural Mineral for Construction & Industry

Discover Vietnamese stone powder, the high-quality natural mineral for construction, industrial, and creative applications worldwide. Sustainable, versatile, reliable.

Vietnam Calcium Carbonate for Kenya – Reliable CaCO₃ Supplier for Industry

High-quality Vietnam Calcium Carbonate (CaCO₃) for Kenya. Ideal for plastic, paint and construction. Stable quality, competitive price, Mombasa delivery.

Vietnamese Stone Powder – Premium Calcium Carbonate Solution for Indian Businesses

Discover high-quality Vietnamese stone powder (Calcium Carbonate) for construction, plastics, paints, and agriculture. Reliable supply, competitive price, perfect solution for Indian companies.

Xem chi tiết

Leading calcium carbonate manufacturer from Vietnam

Tan Ky Mineral is leading manufacturer of calcium carbonate in Vietnam. We own the best quality limestone mines and the most modern grinding technology Hosokawa Alpine - top cut size from 4 micron

Contact Info

Tan Ky Mineral Processing Joint Stock Company

Address: Zone C - Nam Cam Industrial Park - Nghi Xa Commune - Nghi Loc District - Nghe An Province An

Phone/WhatsApp: +84 86 89 89 350

Email:

salesmanager@tankymineral.com.vn

SEND THE MESSAGE

Thank you, we will get back to you shortly after receiving the information.

Use of this website and the services means you agree to our Terms of Use and Privacy Policy.