Application

How CaCO₃ Enhances Paper & Packaging Production: Cost Efficiency, Opacity & Print Quality | Tan Ky Minerals

Discover how high‑quality CaCO₃ (calcium carbonate) from Tan Ky Minerals improves printing paper, packaging board, and high‑brightness applications-boosting opacity, reducing cost, and enhancing print quality

Calcium Carbonate in Paints & Coatings: Whiteness & Particle Size

Learn how whiteness and particle size of CaCO3 improve hiding power gloss, and durability in paints & coatings.

Xem chi tiếtSuperfine Calcium carbonate powder top cut 5 microns

Superfine calcium carbonate powder with a top cut of 5 microns is a high-quality material that has found widespread use in various industrial and commercial applications. Calcium carbonate (CaCO₃), a naturally occurring compound, is processed to different grades depending on its intended use. 5-micron top cut calcium carbonate is an ultra-fine powder with incredibly small particle sizes, making it ideal for specialized applications where finer, more uniform particles are required. This article will discuss the characteristics, benefits, and various applications of superfine calcium carbonate with a top cut of 5 microns.

Calcium carbonate 100 mesh application

100 mesh calcium carbonate refers to the calcium carbonate that has been ground into a fine powder with a particle size that passes through a sieve with 100 mesh openings per inch. The particle size of 100 mesh calcium carbonate typically ranges from 150 microns to 200 microns (0.15 to 0.2 millimeters). This mesh size is coarser compared to fine powders like 2000 mesh or 3000 mesh calcium carbonate but is still useful in various industrial applications, offering good dispersion and physical properties.

200 Mesh calcium carbonate ( Limestone powder 200 Mesh grade)

Calcium carbonate (CaCO₃) is a versatile and widely used mineral that finds application in many industries, including paint, plastics, construction, and paper. The term 200 mesh calcium carbonate refers to a specific particle size of calcium carbonate, which has been finely ground to a size that can pass through a sieve with 200 mesh openings per inch. This finer particle size enhances the material’s properties for various industrial applications. In this article, we will explore the characteristics, uses, and benefits of 200 mesh calcium carbonate.

Calcium carbonate 3000Mesh for glossy paints

Calcium carbonate (CaCO₃) is a versatile and widely used mineral in various industries, including the production of glossy paints. Specifically, 3000 mesh calcium carbonate is a finely ground version of this compound, offering unique properties that make it highly suitable for use in the paint and coatings industry. This article will explore the role of 3000 mesh calcium carbonate in glossy paints, its benefits, and how it enhances the quality of the final product.

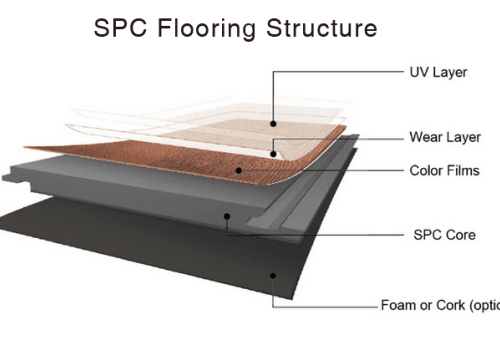

How to Use Calcium Carbonate in SPC Production

Stone Plastic Composite (SPC) flooring is a popular flooring solution known for its durability, water resistance, and ease of maintenance. One of the essential ingredients in the production of SPC flooring is calcium carbonate (CaCO₃), which plays a critical role in improving the performance, cost-efficiency, and overall quality of the flooring. In this article, we will guide you through the process of how to use calcium carbonate in SPC flooring making, detailing its purpose, benefits, and the steps involved in the production.

Calcium Carbonate for SPC Making: Benefits and Uses in Modern Manufacturing

Calcium carbonate for SPC making has become an integral component in the production of Stone Plastic Composite (SPC) flooring, which is gaining immense popularity due to its durability, aesthetic appeal, and cost-effectiveness. This article will explore the benefits, uses, and importance of calcium carbonate in the SPC manufacturing process, while also adhering to SEO best practices to provide valuable insights for manufacturers, designers, and industry professionals.

Calcium carbonate powder for plastic

Calcium carbonate Powder (CaCO3 powder or Ground calcium carbonate) plays a very important role in the plastic industry.

Xem chi tiếtCalcium carbonate for rubber

Choosing the right kind of calcium carbonate (top cut size control) , customers can achieve cost-effective effects by allowing higher calcium carbonate content without affecting the production process as well as final product.

Xem chi tiết

Calcium carbonate powder for paper industry

Tan Ky Minerals Processing Joint Stock Company providing Calcium carbonate powder (Ground calcium carbonate CaCO3), a popular raw material additive in the paper industry, accounts for up to 20% of the paper industry with Ford, Coshce, Briston, Duplex, Ivory, iridescent paper.

Xem chi tiếtOther applications of calcium carbonate

. For feed

. Environmental treatment

. For cosmetic, pharmaceutical , making tooth paste,…

Xem chi tiếtCalcium carbonate for paint manufacturer

Calcium carbonate powder (CaCO3 powder) is mainly used as a substitute for more expensive ingredients. Calcium Carbonate powder by Tan Ky Mineral Processing Joint Stock Company provides proven performance with better value and quality:

Xem chi tiếtLeading calcium carbonate manufacturer from Vietnam

Tan Ky Mineral is leading manufacturer of calcium carbonate in Vietnam. We own the best quality limestone mines and the most modern grinding technology Hosokawa Alpine - top cut size from 4 micron

Contact Info

Tan Ky Mineral Processing Joint Stock Company

Address: Zone C - Nam Cam Industrial Park - Nghi Xa Commune - Nghi Loc District - Nghe An Province An

Phone/WhatsApp: +84 86 89 89 350

Email:

salesmanager@tankymineral.com.vn

SEND THE MESSAGE

Thank you, we will get back to you shortly after receiving the information.

Use of this website and the services means you agree to our Terms of Use and Privacy Policy.

_1.jpg)