Optimizing Masterbatch Formulation with CaCO₃: Secrets to High Whiteness and Excellent Flow

Discover how CaCO₃ enhances masterbatch whiteness, dispersion, and flowability. Learn why particle size and surface treatment are key to performance — and how Tan Ky Mineral provides high-quality CaCO₃ solutions for the plastics industry.

Optimizing Masterbatch Formulation with CaCO₃: Secrets to High Whiteness and Excellent Flow

1. CaCO₃ – A Key Ingredient in Modern Masterbatch Production

Calcium carbonate (CaCO₃) is one of the most widely used fillers in plastic masterbatch manufacturing. It not only improves whiteness, stiffness, and heat resistance, but also helps reduce production costs by partially replacing virgin polymer resins.

As a functional filler, CaCO₃ directly affects:

Melt Flow Index (MFI) – determining how easily the masterbatch can be processed by extrusion, blowing, or injection molding.

Surface brightness and color uniformity – crucial for high-quality end products.

Mechanical properties and long-term stability of the final plastic parts.

2. Why Particle Fineness Matters for Masterbatch Quality

a. Impact of Particle Size on Whiteness and Dispersion

Ultrafine CaCO₃ (average particle size D50 < 2 µm) ensures excellent dispersion in the polymer matrix. Fine, uniform particles help:

Prevent agglomeration or phase separation.

Improve surface gloss and brightness of the masterbatch.

Enhance color distribution when combined with pigments.

b. Fine Powder = Better Flow

When CaCO₃ particles are finely ground and surface-coated with stearic acid or compatible coupling agents, internal friction within the polymer melt decreases. This directly improves the flowability (MFI) of the masterbatch, allowing faster, smoother processing during extrusion and molding.

3. Dispersion Control – The Key to Stable Performance

Uniform dispersion of CaCO₃ in the polymer base determines the color consistency, transparency, and mechanical strength of masterbatch.

Important factors include:

Mixing technology (high-speed mixers or twin-screw extruders).

Processing temperature and residence time.

Surface coating quality of the CaCO₃ particles.

At Tan Ky Mineral Processing JSC, advanced surface modification technology allows CaCO₃ particles to bond more effectively with polymers, enhancing stability and minimizing raw material loss.

4. Benefits of Optimizing CaCO₃ in Masterbatch Formulation

Properly engineered CaCO₃ masterbatch formulations offer a wide range of advantages:

| Performance Factor | Improvement with High-Quality CaCO₃ |

|---|---|

| Whiteness | Increased by 3–5% due to consistent particle size |

| Flowability (MFI) | Improved by 10–15% |

| Machine Efficiency | Increased by 5–10% (reduced friction and faster flow) |

| Raw Material Cost | Reduced by 10–20% vs. 100% virgin resin |

| Color Stability | More uniform and easy to control |

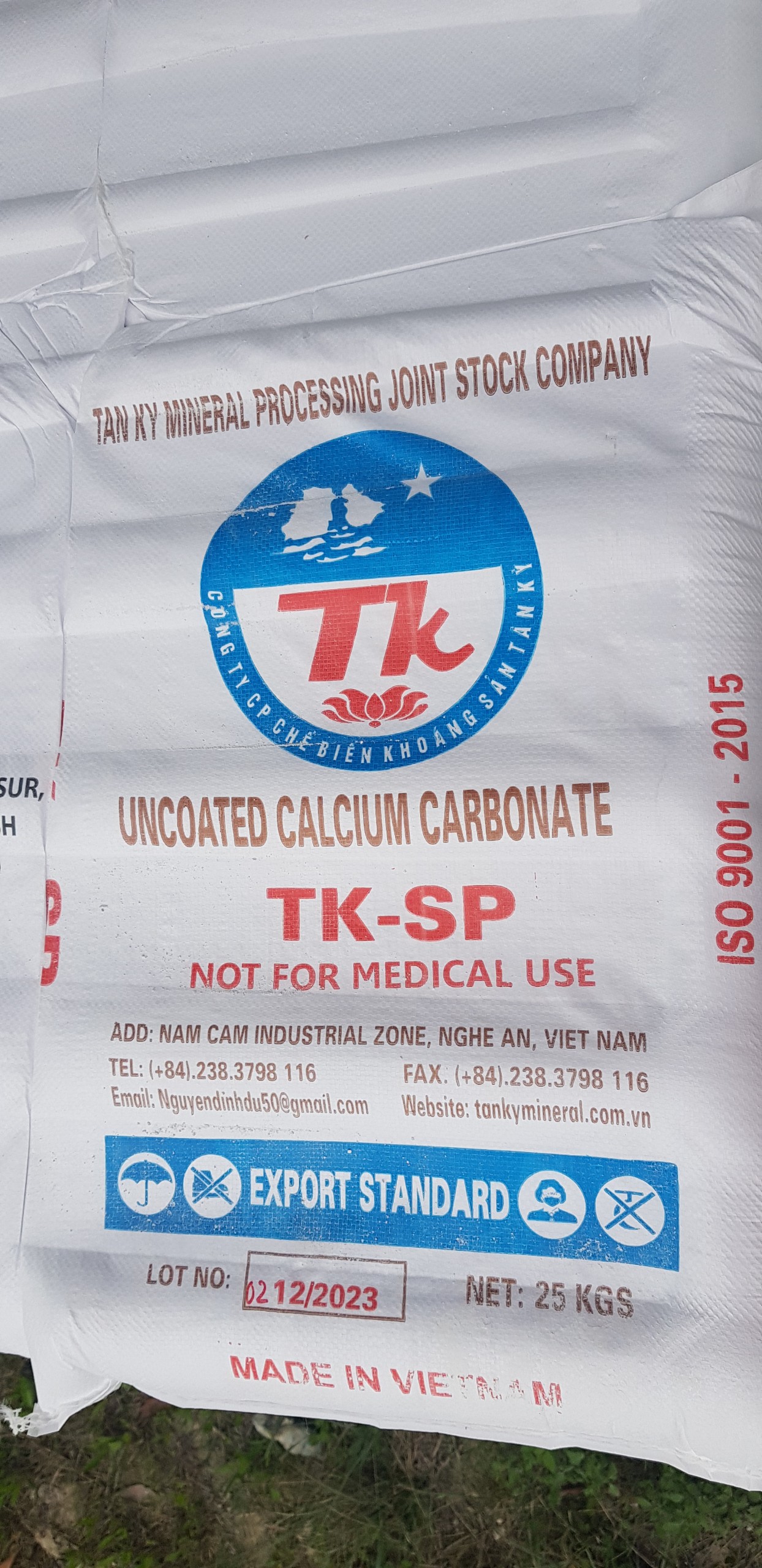

5. Premium CaCO₃ Solutions from Tan Ky Mineral Processing JSC

With decades of experience in mineral extraction and processing, Tan Ky Mineral Processing JSC is one of Vietnam’s leading suppliers of ultrafine CaCO₃ powder for masterbatch manufacturers worldwide.

Key advantages of Tan Ky CaCO₃:

High-purity white limestone sourced from Nghe An, Vietnam.

Modern production lines: crushing, grinding, classifying, and coating in a closed system.

Whiteness > 98%, D97 < 10 µm, ensuring superior brightness and dispersion.

Certified ISO 9001:2015, REACH, and ROHS for international markets.

Tan Ky’s CaCO₃ products are trusted by masterbatch and plastic manufacturers in over 30 countries for consistent performance and competitive pricing.

6. Applications of CaCO₃-Enhanced Masterbatch

Masterbatch containing CaCO₃ from Tan Ky is widely used in:

Plastic film and packaging (PE, PP)

Blow molding and injection molding applications

Rigid plastic sheets, pipes, and profiles

Electrical cables and building materials

CaCO₃ contributes to reduced shrinkage, higher stiffness, and better surface finish, making products more durable and visually appealing while keeping production economical.

Optimizing masterbatch formulation with CaCO₃ is not only a cost-saving strategy, but also a technical solution to improve product appearance and process efficiency.

With premium raw materials and advanced processing technology, Tan Ky Mineral Processing JSC delivers high-performance CaCO₃ solutions that help plastic manufacturers enhance product quality and sustainability.

👉 Contact Tan Ky Mineral Processing JSC today to get a quotation for ultrafine CaCO₃ powder for masterbatch, or

Contact: salesmanager@tankymineral.com.vn

Website: www.tankymineral.com.vn