CALCIUM CARBONATE POWDER SPECIFICATIONS AND USES

Calcium carbonate is an exceptional compound. The chemical formula CaCO3 represents a raw material that exists everywhere in nature – whether dissolved in rivers and oceans, melted as "cold" carbonatite lava and solidified as a mineral, dripstone or as a parent material for whole mountain ranges.

What is calcium carbonate?

Calcium carbonate accounts for more than 4% of the earth's crust. As a result, the three calcium carbonate minerals – calcite, aragonite and vaterite – are among the most important rock-forming minerals. Rocks are not the only calcium carbonate deposits in nature – almost all stretches of water and countless plants and animals contain huge amounts of calcium carbonate as well. These natural resources are linked by the calcium carbonate cycle.

Plants and animals absorb calcium carbonate in water, where it usually exists dissolved in the form of calcium hydrogen carbonate Ca(HCO3)2, and use it to build up their skeletons and shells. After their death, mussels, coccoliths, algae and corals form sedimentary deposits on sea beds and the rock-forming process is set in motion.

The first stage is the sedimentation process, from which chalk and limestone originate. Chalk is a poorly compacted sedimentary calcium carbonate rock whose diagenesis is incomplete.

A completed sedimentation process results in the formation of limestone. If the sedimentation process takes place in water containing magnesium, dolomitization may occur. Part of the calcium ions in the crystal lattice are replaced by magnesium ions, leading to the formation of dolomite (CaMg(CO3)2).

Marble is a metamorphic rock resulting from the recrystallization of limestone under high pressure and temperature. Whether chalk, limestone, dolomite or marble, all carbonate rocks are subject to erosion. These dissolve under the influence of wind, temperature and water, and the cycle is ready to start anew.Vietnam has good sources of CaCo3 and many leading manufacturers

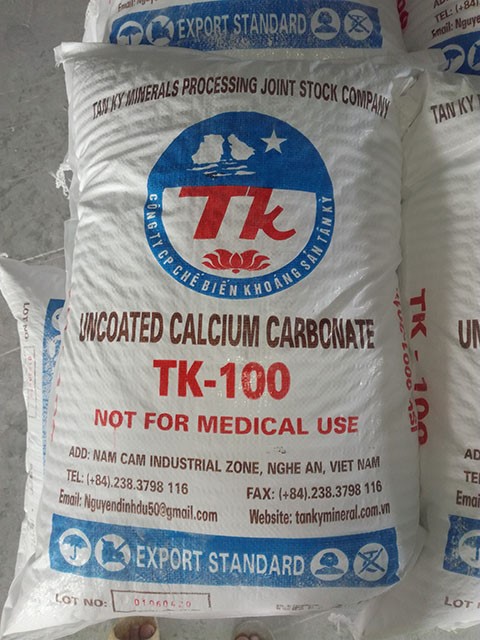

Uncoated calcium carbonate powder by Tan Ky mineral

Calcium Carbonate Specification and MSDS

Most concerned calcium carbonate specifications are related to chemical data and technical data. Let's analyze some of those important datas:

Chemical Data:

These includes CaCO3 content (which should be above 97% for industrial applications as: paint, paper, pvc, pipe,...); Iron oxide (Fe2O3), magnesium (MgO) and silica (SiO2): these contents aren't neccessary and should be keep at low level ( under 0.2%). These chemical datas are often unchangable and relied on sources of CaCo3. So there are only some countries qualified for this criterias: Vietnam, Malaysia, Egypt...

Technical Data:

These includes whiteness; brightness; moisture content; oil absorption and PH value which are very important to consider uses in every application.

Fineness :

While other datas are almost permanent, fineness is set by machine. Raw calcium carbonate (lump) needs to be grinded into powder for industrial uses as additives. Manufacturers need to set up a production line for this work. At first, there were only some machines from top-producers qualified for this task: Hosokawa Alpine machines. Then Chinese producers started to jump into this field by producing lower price machines which only can produce rougher Calcite Powder ( to some certain levels of particle size). Fineness is determined by D50 (median size); D97 (top cut) and sometimes by mesh size; D97 under 10 µm should be considered as hight quality powder that is often used in high-profit fileds such as PVC;pipe,...

Calcium Carbonate Uses

Calcite is a naturally occurring mineral; it is subject to considerable variation. Its industrial application depends upon properties such as composition, particle size and shape, specific gravity, hardness, and color.

1.) Calcite Powder Use in Paper: In the paper sector, micronized calcite has been used in paper and cardboard production by adding it into cellulose in different proportions. Since calcite increases the whiteness of paper, naturally.

2.) Calcite Powder Use in Paint: The excellent whiteness of our carbonates avoids interference with the paints colors and contributes to their opacity and that the paint will cover, without dripping, the surfaces.

3.) Calcite Powder Use in Plastic: Calcite mineral widely used as mineral fillers in order to obtain high humidity retention, to improve the consistency and dryness of the final mass. These polymers have various applications like in bags, pipes, automotive parts, furniture, containers etc.

4.) Calcite in Cosmetics: Calcite is widely used in the cosmetics industry in make-up, soaps, toothpastes etc. Use of calcite imparts many benefits in making cosmetic products

5.) Calcite in Glass: Calcite powder for glass industry must compose of a high and consistent percentage of CaO and be devoid of color imparting impurities like Fe2O3 etc. Rajasthan is an excellent source of high whiteness calcite.

6.) Calcite in Ceramic: Our calcite is used in every kind of ceramic product manufactured including art ware, porcelain, pottery, floor tiles, sanitary ware to name a few.

They all use basic uses of Calcite offers by Tan Ky Mineral Processing JSC , who is a leading calcium carbonate manufacturer in Vietnam .For more details, feel free to contact us.

www.tankymineral.com.vn

Mob/what'sapp: +84 86.89.89.350

Email: talia.tkmineral@gmail.com