Application of CaCO₃ in the Rubber Industry – Improving Mechanical Strength, Enhancing Abrasion Resistance, and Optimizing Production Costs

Discover how calcium carbonate (CaCO₃) improves the mechanical properties of rubber, increases abrasion resistance, and reduces material costs. Contact us for a CaCO₃ quotation and download our product catalogue.

https://tankymineral.com.vn/application

Why Choose Calcium Carbonate for Rubber Production?

In the rubber manufacturing industry—from tires, hoses, mats, and shoe soles to technical rubber parts—the choice of additives is crucial.

One of the most common and effective fillers is Calcium Carbonate (CaCO₃), also known as ground marble or limestone powder.

CaCO₃ brings three major benefits to rubber compounding:

Improves mechanical strength (tensile, tear, hardness)

Increases abrasion resistance and product durability

Reduces production costs and stabilizes product quality

Below we’ll explore how CaCO₃ enhances mechanical properties, saves costs, and improves consistency—complete with process and application visuals, and clear call-to-action prompts.

How CaCO₃ Improves the Mechanical Properties of Rubber

Role as a Filler in the Rubber Matrix

CaCO₃ acts as a filler, dispersing throughout the rubber matrix to improve basic physical characteristics.

Studies have shown that “NR/treated CaCO₃ composites provide higher tensile strength than NR/untreated CaCO₃ composites.”

In essence, treated calcium carbonate improves bonding between particles and the rubber polymer.

Key effects include:

Higher hardness and modulus: Adding CaCO₃ increases rigidity, reducing deformation.

Improved tear and cut resistance: Filler particles distribute stress evenly, reducing tear propagation.

Enhanced abrasion resistance: Ideal for friction-heavy products like conveyor belts, soles, and tires.

Factors Affecting Performance

The effectiveness of CaCO₃ depends on:

Particle size: Finer particles (smaller D50) have greater surface area and better dispersion.

Surface treatment: Coated CaCO₃ (e.g., stearic acid coating) improves compatibility with rubber.

Filler ratio: Excessive filler may reduce tensile strength—balance is key.

Stabilizing Product Quality

Due to its fine particle size and uniform distribution, CaCO₃ ensures consistent quality by:

Producing smoother, more uniform rubber surfaces.

Reducing shrinkage and deformation during vulcanization.

Making mixing and molding processes more stable and predictable.

Cost Reduction and Production Efficiency

CaCO₃ – An Economical Filler Solution

Calcium carbonate is an affordable natural mineral, significantly cheaper than synthetic fillers or polymers.

By partially replacing raw rubber or carbon black with CaCO₃, manufacturers can lower production costs while maintaining technical performance.

Improving Production Efficiency

CaCO₃ enhances process stability during mixing, vulcanization, and molding.

Reduces energy consumption and material waste by improving thermal control.

Decreases defective rates thanks to better homogeneity and lower internal stress.

Key Considerations

To achieve optimal results:

Avoid overloading the filler ratio.

Choose the right type of CaCO₃ (particle size, coating) for your product.

For high-wear applications, use ultra-fine coated CaCO₃ grades.

Real-World Applications of CaCO₃ in Rubber

Product Examples and Use Cases

Shoe soles and rubber mats: Increased hardness and abrasion resistance.

Conveyor belts and hoses: Extended service life, improved dimensional stability.

Tires: Reduces raw material cost while maintaining durability.

Technical rubber parts: Enhanced modulus and tear strength.

Typical Production Process with CaCO₃

- Prepare natural/synthetic rubber and additives

- Prepare natural/synthetic rubber and additives

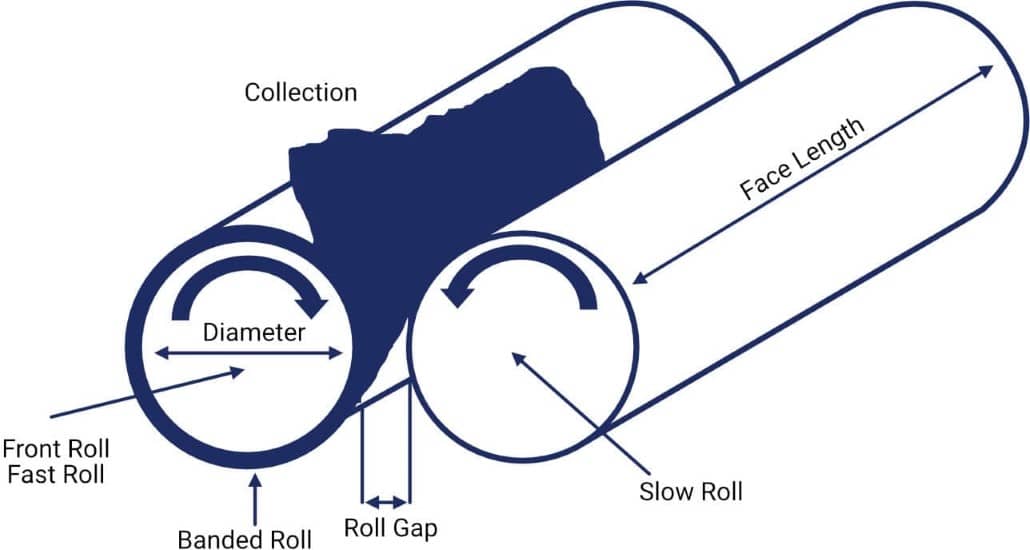

- Add pre-treated CaCO₃ powder into the mixing mill

- Mix thoroughly for uniform filler dispersion.

- Mold or extrude and vulcanize the compound.

- Inspect mechanical and abrasion properties.

CaCO₃ helps create stable, durable, and cost-effective rubber compounds across various applications.

Why Choose Our Company’s CaCO₃

We are a leading manufacturer and supplier of calcium carbonate (CaCO₃) in Vietnam, specializing in high-quality fillers for the rubber, plastic, and paint industries.

Our Strengths:

High-purity raw materials (CaCO₃ ≥ 98 %) with bright whiteness.

Modern production lines meeting ISO 9001:2015 standards.

Consistent particle size (D50 5–10 µm) suitable for technical rubber.

Technical consulting service to ensure optimal filler selection and usage.

With advanced facilities and strict quality control, we provide stable quality, competitive pricing, and fast nationwide delivery.

Contact: salesmanager@tankymineral.com.vn