Can Limestone Powder Replace Part of Cement in Concrete? A New Anti-Corrosion Solution for Coastal Projects in the Philippines

Explore how limestone powder (CaCO₃) can partially replace cement to improve durability and saltwater resistance in Philippine coastal and island construction projects.

https://tankymineral.com.vn/can-limestone-powder-replace

Can Vietnamese Limestone Powder Become an Anti-Corrosion Additive for Concrete in the Philippines?

With more than 7,600 islands, the Philippines has one of the highest densities of coastal infrastructure in Southeast Asia. Ports, roads, bridges, airports, and resorts built along the shoreline constantly face:

Chloride corrosion from seawater

Rising cement prices

The need for more durable materials in marine environments

Because of these challenges, engineers in the Philippines have begun experimenting with limestone powder (CaCO₃) as a partial replacement for cement. This approach is already common in Europe and is now emerging in Southeast Asia—especially in countries with large coastal construction needs.

The key question is:

Can high-quality Vietnamese limestone powder become a strategic anti-corrosion additive for Philippine concrete?

Let’s explore the science, benefits, applications, and market potential.

Limestone Powder – A Rising Global Trend in Concrete Technology

Limestone powder (Ground Calcium Carbonate – GCC) is widely used in:

Cement production

Mortar and plaster

Concrete mixes

Block and paver manufacturing

Modern research shows that CaCO₃ does more than act as a filler. It helps:

Increase early-age strength

Improve packing density of concrete

Reduce pore volume

Enhance resistance to chloride penetration

These advantages make limestone powder especially valuable for marine and coastal construction—an area where the Philippines has major demand.

Production Process of Construction-Grade CaCO₃

Below is the standard process used by leading Vietnamese manufacturers:

High-purity limestone mining

Materials are sourced from white limestone mountains with CaCO₃ content ≥ 97–98%.

Crushing & impurity removal

Magnetic separators eliminate heavy metals and impurities.

Fine grinding

Typical particle sizes for concrete are:

8–20 microns → high-performance concrete

20–45 microns → ready-mix concrete

→ high-density, low-porosity concrete

Particle size classification

Air classifier systems ensure tight particle size distribution.

Quality control

Checks include brightness, moisture, purity, fineness.

Packaging & shipment to the Philippines

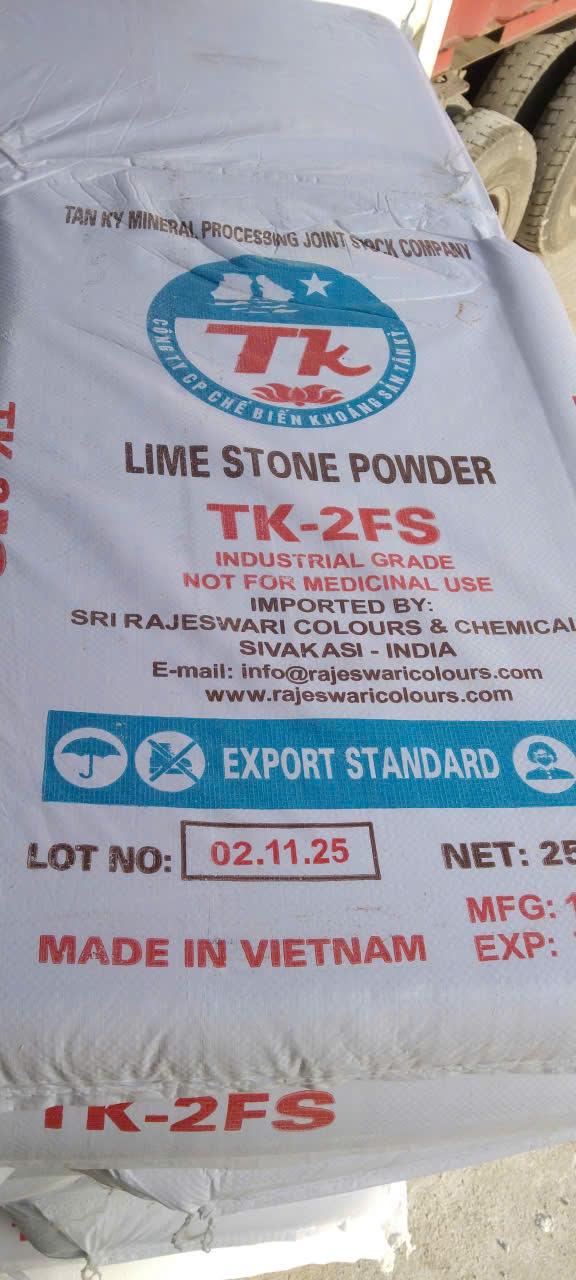

25 kg bags or 1–1.35 ton jumbo bags shipped to Manila, Cebu, Davao within 5–8 days.

Why Can Limestone Powder Replace Part of Cement?

“Filler Effect” – Improves concrete density

Fine CaCO₃ particles fill micro-voids between cement grains, creating a:

Denser matrix

Lower capillary porosity

Reduced water and chloride penetration

This is a major benefit for marine structures.

Accelerates early hydration

Limestone powder works as a nucleation site, helping cement hydrate faster and gain early strength.

Reduces heat of hydration

Ideal for island or offshore projects where temperature control is critical to avoid cracking.

Cuts cement consumption by 10–20%

This is especially important in the Philippines where large volumes of clinker and cement are imported.

Applications in Philippine Marine & Coastal Projects

Limestone powder is being tested in several types of projects:

Ports and wharves

Seawalls and breakwaters

Coastal roads

Beach resorts and island villas

Bridges and piers

Pilot projects in Cebu, Davao, Manila Bay, Coron, and Palawan have tested 5–15% cement replacement.

Preliminary results show:

Stronger resistance to chloride attack

Smoother, denser surface texture

Lower permeability

Reduced cracking

More cost-efficient concrete mixes

Better long-term durability near seawater

This positions CaCO₃ as a promising eco-friendly additive for the Philippines.

Why Vietnamese Limestone Powder Fits the Philippine Market

✔ 1. High purity and whiteness (≥ 97%)

Ideal for visible structures like beachfront resorts.

✔ 2. Consistent particle size distribution

Critical for achieving predictable concrete strength.

✔ 3. Lower price vs. Turkey and China

Vietnam–Philippines shipping routes are short and affordable.

✔ 4. Large, stable supply

Vietnam is Southeast Asia’s largest CaCO₃ exporter.

✔ 5. Compliance with international standards

ASTM – EN – ISO (varies by manufacturer).

Because of these advantages, Philippine importers increasingly prefer Vietnamese CaCO₃ for both concrete and other industries.

Challenges & Considerations When Using CaCO₃ in Concrete

Not all limestone powder is suitable for cement replacement. Engineers must consider:

Particle size – too coarse reduces strength

Moisture content – affects water demand

Shape and texture – irregular particles reduce density

Impurities (MgO, SiO₂) – can weaken concrete

This is why many contractors in the Philippines prefer suppliers with Air Classifier Technology to ensure quality and consistency.

Future Outlook – A New Material Trend for Philippine Construction

With increasing investment in:

Coastal highways

Airport expansions

Port modernization

Island tourism infrastructure

Flood protection and seawalls

The Philippines will require millions of tons of durable, anti-corrosion concrete.

Limestone powder is a cost-saving, performance-enhancing, marine-grade additive that aligns perfectly with the country’s construction challenges.

Vietnam, with its abundant limestone reserves and advanced processing technology, is positioned to become the Philippines’ top CaCO₃ partner in this sector.

The idea that “Vietnamese limestone powder can become an anti-corrosion additive for concrete in the Philippines” is not just theoretical—it's highly practical and increasingly supported by real-world applications.

By replacing 5–15% of cement, CaCO₃ can:

Improve durability

Boost chloride resistance

Reduce cracking

Lower construction costs

Extend the lifespan of marine structures

This makes limestone powder a game-changing material for the Philippine construction market in 2025 and beyond.

- Contact: salesmanager@tankymineral.com.vn

Website: www.tankymineral.com.vn

.jpg?1764830841740)