The Effect of Grounded Calcium Carbonate on the Physical Properties of NR Vulcanised Latex Films

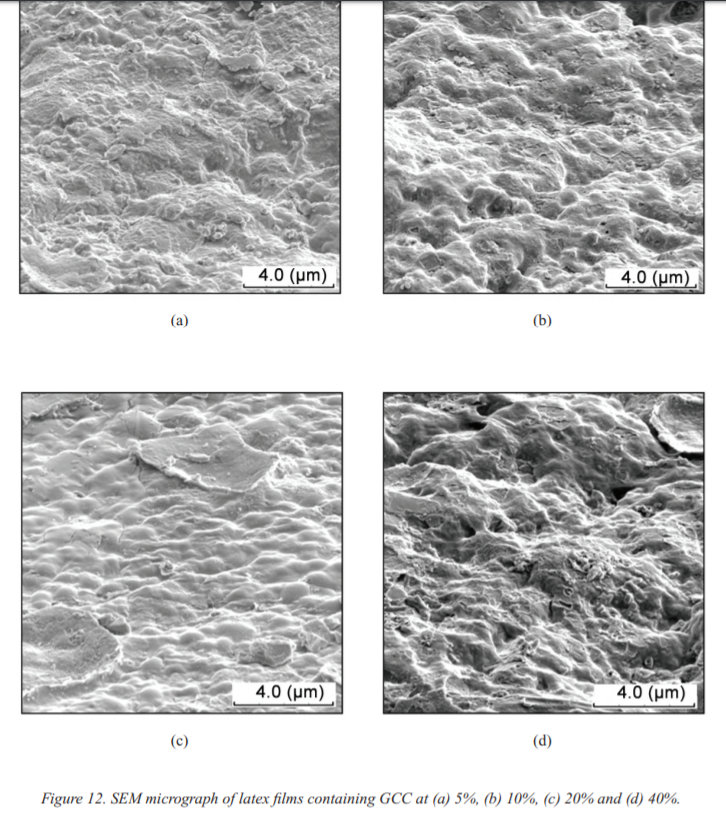

The application of GCC affects the properties of NRL films. The tensile strength and force at break values improved at low levels of GCC but dropped when GCC loading is more than 5% in NRL films. The elastic constant of unscragged NRL films increased with filler loading. Scragging disturbed the filler arrangement and the reinforcement mechanism diminished. SEM technique allows visualisation of surface smoothness of NRL films due to filler addition. However, this observation is inconsistent as only the film with 20% GCC appeared to be smooth as seen in the SEM micrograph, while FIB-SEM provides a better relationship between differently filled NRL films with more spots due to filler clustering as observed with increased GCC levels in the NRL fil

The effect of filler loading on tensile strength, force at break, modulus, stress-strain relationship and surface morphology of natural rubber latex (NRL) films was studied. Grounded calcium carbonate (GCC) loaded into NRL latex compounds and the results obtained from latex films formed from these compounds, showed that their tensile strength and force at break improved initially but leveled and dropped when the GCC loading is more than 5% in NRL films. Disturbing the filler arrangement in the rubber matrix by scragging the test piece of filled NRL films changed the elastic constant value (C1) of the filled test pieces with a large difference in highly filled films. Expected agglomeration of filler in gloves visualised via the microscopy technique indicated disinclination of GCC to distribute well in NRL films. The discrepancy seen in SEM micrographs between differently filled films could be related to surface roughness of the NRL films. Among filled NRL films, the one containing 20% of GCC had the smoothest appearance in its surface morphology. Micrographs from FIB-SEM techniques show clear clustering of fillers at high dosages in the NRL films.

Keywords: Natural rubber latex; filler; calcium carbonate

Compounded natural rubber latex (NRL), due to its dried film characteristics, is normally the preferred material for producing thin rubber products. Among the common products from NRL are latex gloves, balloons, condoms and catheters. The peculiarities seen in NRL films such as high elasticity and flexibility at low modulus compared to films made from dry bulk rubber, give an advantage to NRL in meeting the usage demands of these NRL products. Most products are to meet a set of minimum quality requirements based on their application to ensure safety in usage. It is undeniable that a main contributor to the cost of producing NRL gloves is the bulk material in the gloves. The rubber content in NRL gloves of more than 95% is believed to be one of the reasons for the high strength superiority of NRL gloves. However, in recent years, due to the increased price of NRL, filler is added into latex to cheapen material cost. Surprisingly, these filled gloves meet the minimum requirements of current regulatory limits; hence, they are acceptable to consumers. With this attractive savings in cost, glove makers are pushing the limit of fillers in NRL gloves. Cai et al. 5 were among earlier workers reporting that ultrafine calcium carbonate could effectively improve tear strength, tensile strength and modulus of the NRL films. Improved modulus reflects an increase in stiffness of NRL films. It is thought that further stiffening an elastic thin product by incorporating high levels of a nonelastic material such as a filler, may render the product useless for its purpose. Therefore, this paper is intended to demonstrate this effect on NRL films.

SUMMARY

The application of GCC affects the properties of NRL films. The tensile strength and force at break values improved at low levels of GCC but dropped when GCC loading is more than 5% in NRL films. The elastic constant of unscragged NRL films increased with filler loading. Scragging disturbed the filler arrangement and the reinforcement mechanism diminished. SEM technique allows visualisation of surface smoothness of NRL films due to filler addition. However, this observation is inconsistent as only the film with 20% GCC appeared to be smooth as seen in the SEM micrograph, while FIB-SEM provides a better relationship between differently filled NRL films with more spots due to filler clustering as observed with increased GCC levels in the NRL films.

A research of MOHAMAD AKMAL A.R*#, SITI NOR QAMARINA M.* AND AMIR HASHIM M.Y.*

Please check full details as link below:

Akmal_2013_effect_grounded_calcium to latex glove